Login

Registered users

Plastics made from finite resources have posed a growing threat to the environment since World War II. If they’re not recycled, many of the plastics that we use every day in our homes end up polluting the seas and oceans.

In this article we’re looking at two solutions that architects and researchers have developed to address the problem of ocean pollution in an ecological and sustainable way.

In the Cocos (Keeling) Islands – a small archipelago in the Indian Ocean, midway between Australia and Sri Lanka – increasing levels of plastic pollution are damaging whole ecosystems. Every year, huge numbers of hermit crabs are becoming trapped in plastic waste and dying. These crabs play a crucial role in the tropical environment and their disappearance would have significant impacts on both this and the surrounding ecosystems.

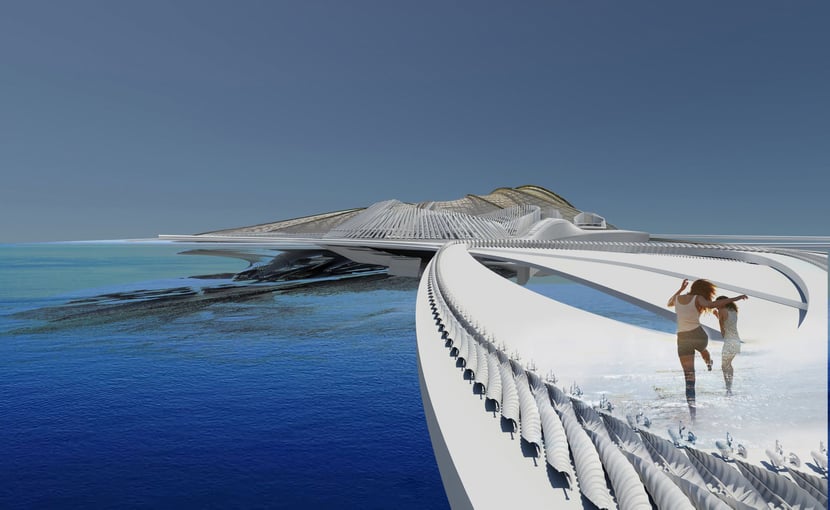

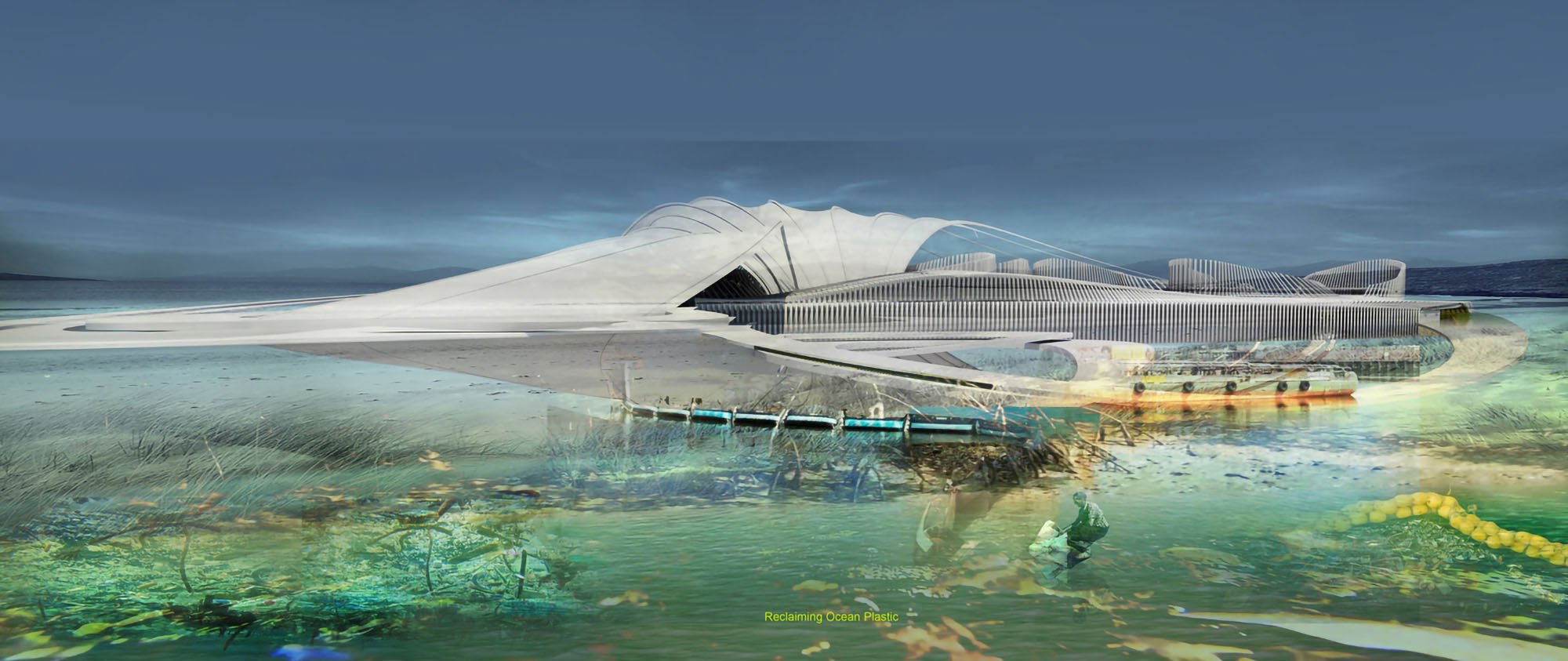

Margot Krasojević Architects has designed a floating hotel that collects and manages plastic waste in the ocean. Using software that simulates the ocean current, the studio first mapped the movement of floating plastic waste. This was the starting point for devising a system to collect the waste and put it to constructive use. From here, the idea was born to use this plastic as a building material for a floating hotel, whose structure could evolve parallel to the accumulation of the waste that serves as the floating base of the facility.

This artificial island will be made up of mesh-filled bags of reclaimed plastics from the ocean. The entire structure will then be anchored to the ocean floor, and sand and silt will be deposited on the plastic flotation devices as a kind of landfill. Mangrove trees will then be planted in the landfill, whose roots will grow around the mesh-filled plastic bags to create a stable structure. Mangrove trees are often used for flood prevention precisely because of the way they trap sediment in this way.

The facility will offer guests both indoor accommodation and camping areas. The showers will use filtered, distilled sea water, pumped into the facility using solar energy. The entire island will be a highly sustainable project, able to collect polluting plastics scattered across the Indian Ocean.

Marco Caniato, a researcher with the Faculty of Science and Technology at the University of Bozen-Bolzano, has combined an extract from agar with plastic powders, derived from marine plastic waste, to develop a product that can be used to insulate buildings.

Secondary microplastics – that is, plastic particles less than 0.2 inches (5 mm) in size that result from the breakdown of waste objects, such as plastic bags and bottles – make up approximately 68–81% of the microplastics present in our oceans (source: European Parliament).

In 2017, the UN stated that there were as many as 51 trillion microplastic particles in the seas: “five hundred times more than stars in our galaxy.” Worldwide, our seas have been described as one of the worst polluted areas by micro- and macroplastics. As a result, the treatment and lifecycle management of plastics has become a huge problem.

A product invented and patented by Marco Caniato, however, has proven to be extremely promising in the battle against the dispersion of microplastics in the environment. Caniato has developed a biopolymer that’s a very effective thermal and acoustic insulation for industrial, civil, and maritime applications.

Working in collaboration with the University of Trieste, Caniato’s team started with an agar extract – a polysaccharide normally used as a natural gelling agent. Calcium carbonate is added and then the powdered plastic. After the resulting gel forms, the samples are frozen at -4°F (-20°C) for twelve hours and finally lyophilized to remove the water. The result is a porous material that can be used to replace rockwool insulation, for example. But it’s not only the product itself that’s eco-friendly. The manufacturing process involves recycling the water collected at the end of the freeze-drying process.

“Our characterization tests have confirmed that our product has excellent insulation properties and can easily keep up with conventional insulation materials such as rockwool and polyurethane foams,” says Caniato. “We’ve therefore demonstrated that a sustainable, cleaner, and eco-friendly approach can be used to recycle marine waste and create a new, eco-friendly material.”

Read the article: Acoustic and thermal characterization of a novel sustainable material incorporating recycled microplastic waste